A Beginner’s Guide to Using a Paper Bag Making Machine

As the environment becomes more of an issue, paper bags now are a desirable, green alternative to plastic packaging. With a shift in environmental preference towards more sustainable choices, paper bag manufacturing service demands keep increasing. You have, at your disposal, a detailed introductory material on the operation of a paper bag making machine and you can make an informed investment decision with industry leaders such as Ronald India because this all-encompassing guide will have you covered.

Learn everything about the whole process of producing paper bags to be skillful on using the equipment.

Before the efficient use of paper bag making machine, it is advisable that you become conversant with the paper bag making process. The whole production cycle starts when the kraft paper is fed into the machine. From there, the machine handles:

- Paper folding

- Side pasting

- Bottom formation

- Bag cutting

- Optional printing or punching

All the phases require defining the proper parameters, speed, accuracy and consistency are of prime importance for effective production of bags of superior quality.

Variations of paper bag making machines that are in the market.

I believe that when deciding on which machine would be the most appropriate to own, you need to consider your production needs. The most common types include:

-

Fully automated equipment that can process all the stages of the production of bags.

Such types of machines are excellent in producing bags in large quantities commercially. Their design includes integrated elements for printing, pasting, folding, and forming the bag’s bottom.

-

Semi-Automatic Paper Bag Making Machine

Practical enough for businesses with little to spare. However, manual intervention might be done on some steps like gluing the handles or printing messages.

-

The flat and Satchel Paper Bag Machinery.

These devices are ideal for making flat paper bags, both with and without gussets that are highly common in pharmacies, bakeries, and grocery shops.

-

Square Bottom Paper Bag Machine

A frequently observed application in food delivery, upscale fashion retail, and high-end packaging.

Essential Parts of a Machine for Making Paper Bags

The basic components of a paper bag making machine are essential to its operation.

- Paper Roll Feeding Unit: Delivery Unit: Receives finished paper bags in order.

- Folding Section: Makes the paper fit properly so that it can make folds that also fit the bag’s dimensions.

- Gluing System: Applies adhesive on side flaps.

- Bottom Formation System: Creates the base of the bag with accurate folds and gluing the bottom.

- Delivery Section: Collects finished bags in order.

Some machines can have on them handle-sealing units, flexography printers, and window lamination devices.

Manual on how to use a paper bag making machine.

Step 1: Setting Up the Machine

Position the machine on a stable and level surface and provide adequate static-protecting electrical grounding for safety concerns. Correctly place the kraft paper roll on to the unwinding shaft.

Step 2: Paper Feeding and Alignment

Make the paper go through the rollers and put it in the position as indicated by folding and gluing guides. Lock in alignment sensors and controls to ensure correct positioning of the paper during production.

Step 3: Adjusting Bag Dimensions

Have the machine programmed to define specific dimensions for length, width, gusset and bottom size. Step 5 is Cutting and Collection; the machine will automatically cut and stack the finished bags; ensure consistency in cutting length and fold accuracy.

Step 4: Monitor Adhesive Application

Use only high-quality water-based adhesives. Ensure to spread the adhesive well for a strong seal in the bag formation process.

Step 5: Cutting and Collection

Machine will automatically fend for cutting and collection of the completed bags. Ensure that each bag is cut to the correct length and that folds are aligned correctly at all times.

Tips for First-Time Users

- Trial roll of kraft paper should be used to understand on how the machine operates at the beginning.

- Conduct routine checks to rollers, blades, and the machine used in application of glues.

- First class raw materials ensure superior output.

- Recording output metrics will help in identifying trends and thus correct issues in a manner as effective as possible.

Maintenance and Troubleshooting

Machine maintenance is vital in the machine’s life as well as production of high quality output. Follow these tips:

- Daily Cleaning: After every shift, completely wash the machine to remove any remaining paper dust and adhesive left overs.

- Blade Sharpening: It is important to ensure cutting blades are sharp in order to produce clean cuts as needed.

- Greasing Bearings: A proper flow of lubrication reduces friction and increases machine life.

- Monitor Motor Temperature: Overheating can indicate electrical faults.

- Replace Worn-Out Parts: Check belts, rollers and gears every three months for wear.

It is best left to certified technicians as well as to the manufacturer’s help team to deal with such frequent issues as paper jams, adhesive leaks, or misalignment.

And here’s why professionals in the industry opt for Ronald India Paper Bag Making Machines.

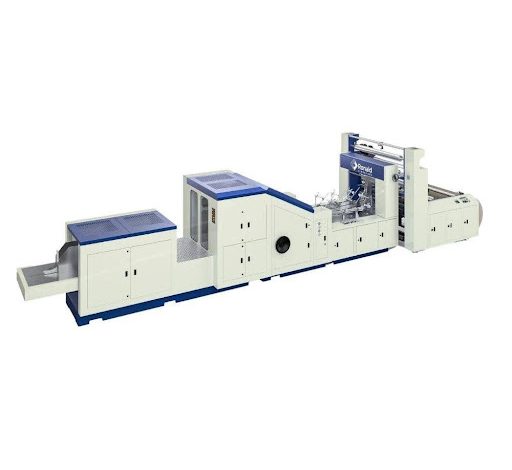

Ronald India leads the pack in the production of paper bag machinery. in reply

- Advanced Automation: Using touch screen displays, PLC controllers, and servo technology.

- Versatile Output: The machines facilitate the production of various bag varieties, including ones with and without handle elements.

- Technical Support: A comprehensive installation support, qualified training, and customer support post transaction.

Their range of machines ranges from basic semi-automatic machinery to super high-tech fully automatic systems that include inline printing and integrated handle installation.

Reasons to Consider Using a Paper Bag Making Machine

- Eco-Friendly Business Model: Hunters capture the growing market interest in the sustainability of packaging methods.

- High ROI: Cost effective production and ability to vary production upwards where necessary.

- Customization Options: Users can quickly switch to different bag sizes and kinds to address special needs.

- Low Labor Requirement: Automated systems eliminated a lot of staff required for production.

Conclusion

Taking to Ronald India paper bag Machine puts you in line with the fast changing trends in sustainability and green business activities. Learning skills using the machine for paper bag production is the first step to launching a profitable and green enterprise of packaging. When you look for products from well-known companies, including Ronald India, you guarantee that your business receives reliable work and creative technology vital to the eco-focused industry for success.