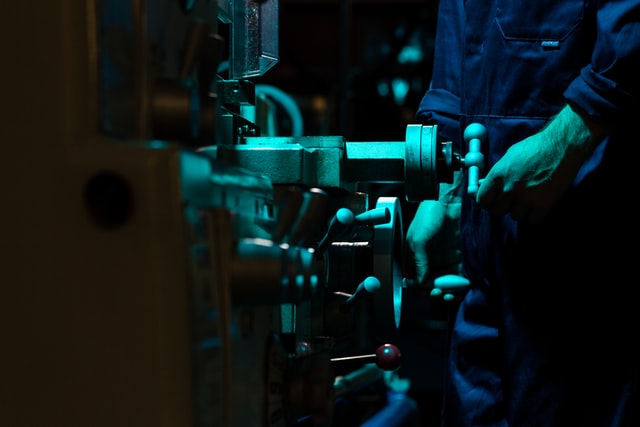

Some components of modern machinery are as important as bearings. You can find them in almost every machine or device designed to move. Bearings and bearing parts activate rotation by reducing stress that occurs by friction. The manufacturing of bearings and bearing cover is possible on CNC machines.

In this guide, I will look at the parts that make up a bearing. As well as any particular considerations you may desire to provide for each part. In case you are designing a bearing for the product or your device. I will also look at the relationship of CNC machines to bearings manufacturing.

What is a bearing?

A bearing is a mechanical part whose job is to guide a rotating assembly. Because of this the bearing allows one element to rotate against the other. So, bearings are high-precision parts that allow device to move at different speeds. The practice takes place by transferring significant loads in effective way. They have to propose high precision and durability. As well as have to offer the possibility of working at high speeds. Moreover, this process will be complete with minimal noise and vibration.

Application and types of bearings:

The manufacturing of bearings requires CNC milling and turning machining services. We can often find this type of device in all applications, such as;

- The automotive industry

- The aerospace sector

- Construction equipment

- Machine tools, etc

Among many types of bearing, the following four main types are;

- Ball bearings

- Cylindrical roller bearings

- Tapered roller bearings

- And needle bearings

Yet, ball bearings have very common mechanisms. Each device contains some advantages and disadvantages. That’s why I will suggest you to compare each of these bearings. The purpose is to find out the ideal system as per your need.

Components of the bearings:

The detail about the components of the bearings is as under;

-

Outer race:

Outer and inner races of bearing present accommodation to balls for rest purposes. A groove cut along the inner frame of the race to hold the balls in place. If the outer race exposes to extreme forces, it will crack. So it is important to make a suitable design for the job. Moreover, always make the outer race with appropriate material.

-

Inner race:

The inner race is a small ring on which the shaft mounts along the groove. The shaft mounts in the outer frame instead of its inner frame. The manufacturer places it in the inside of the outer race. The location on that the balls will be available between the two races in the bearing. The grooves allow the balls to rotate in a freeway in inner and outer racing. But the grooves also prevent them from falling out of the bearing. The design and material requirements for the inner race are the same as the outer race. The main purpose of this is for durability and long-lasting.

-

Bearing retainer:

If the balls need to keep certain spacing in the bearing. And this is a normal situation that occurs in various conditions. I recommend you use a bearing retainer to hold them in place. When you will place the balls inside the bearing retainer. They can still rotate in a freeway around their axis. But a restriction will be available in their way. And they cannot move towards or away from each other in a freeway.

-

Bearing cover or bearing shield:

Bearing shields or bearing covers are available to close the bearing. These prevent dust and other contaminants to disturb the important components inside. Moreover, it is pertinent to mention that bearing shields have an extra job. They are able to maintain the bearing’s lubricant in place longer. For these two reasons, bearing covers are essential to prolong the life of your bearings. If dust or any other particles get inside the bearings, they will be very harmful. That’s why the bearing covers work as an essential component.

-

Balls:

The balls are available between the outer and the inner races of the bearing. The balls allow the bearing to rotate in a freeway. The friction in races will make the bearing useless without the balls. So be sure to use balls that are of good quality. It will cost you more but guarantee that their performance will not be poor. Also make sure that the surface finish of the balls is good. As it also plays an important role in the mechanism of the bearings.

Sourcing high-quality CNC machining services for bearings components:

The sourcing is a very sensitive part for the best quality components of the bearings. If you get the best CNC machining services, it will be good. As if the quality of the components of the bearings is pure, it will be useless. You can find quality CNC turning and milling machining services from China. First, find the appropriate manufacturer of the components for bearings.

Find out that the machining services provider must have the following facilities;

- CNC turning machining services

- milling machining services

- CNC grinding services

- wire cutting electrode discharge machining services

Final words:

The purpose of writing article is to provide valuable information about the bearings. The detailed guide will help you to understand the deep knowledge. The comprehensive definition of the bearing mentioned in the opening. Then I covered about the main components of the bearings. Every single detail mentioned for deep understanding purposes.

If you are new to bearings, you must do some study and research work. It will help you to choose the appropriate services provider as per need.